The ripstop technology in tactical uniforms is a key component of the equipment of professionals who face challenges in extreme conditions every day. This innovative fabric manufacturing method guarantees unparalleled durability and abrasion resistance, while remaining lightweight and comfortable to wear

What is ripstop technology in a tactical uniform?

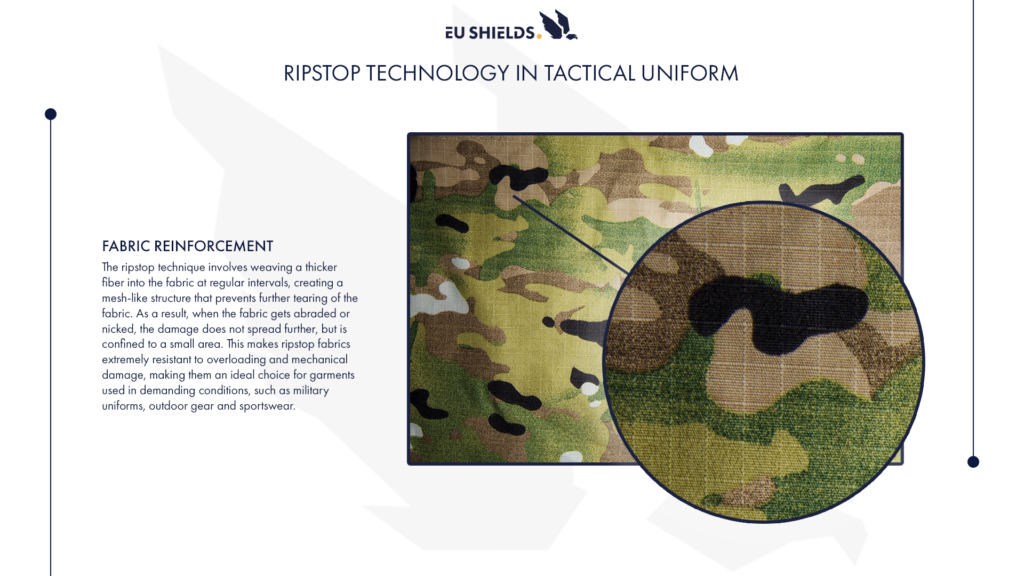

The ripstop technique is a method of reinforcing the fabric, which involves the use of thicker fiber woven in at regular intervals, creating a characteristic mesh-like structure. This gives the fabric increased resistance to tearing and abrasion. In tactical uniforms, where durability is as important as mobility, ripstop works perfectly, providing users with the necessary protection in harsh field conditions.

A key advantage of ripstop technology is its ability to resist further tearing. Thanks to the mesh reinforcement, even in the event of an abrasion or cut, the damage remains confined to a small area, allowing continued safe use and easier repair.

Why are ripstop uniforms the choice of professionals?

Ripstop uniforms have won praise among professionals for their reliability and resistance to harsh terrain. In the defense and tactical industries, where every piece of equipment must respond to unique requirements, ripstop fabrics guarantee the durability that is needed in extreme situations. Their structure is designed to withstand intensive use and ensure maximum safety in every aspect of the mission.

When choosing ripstop uniforms, professionals are also guided by the issue of functionality. The material makes it possible to design garments that combine durability with the necessary mobility, enabling efficient performance of tasks without movement restrictions. What distinguishes ripstop is its adaptability to a wide variety of conditions, making it an ideal choice for those who rely on reliability and readiness to perform in any situation.

Key advantages of ripstop fabric uniforms

Uniforms made of ripstop fabric are distinguished by significant advantages that make them indispensable in many operational situations. The first is the extraordinary durability against tearing and abrasion, which is crucial for those who are exposed to intense contact with rough terrain or sharp objects in the course of their tasks. This durability ensures that the garments last longer, reducing the frequency of replacement and associated costs.

A second important feature of ripstop uniforms is their ability to maintain structural integrity even after damage. In traditional fabrics, a small tear can quickly lead to more serious damage. In the case of ripstop, a specific web construction prevents cuts from spreading, allowing the garment to remain functional and aesthetically pleasing for a long time, even in demanding conditions.

Ripstop in practice: where does it work best?

Ripstop, thanks to its unique properties, is used in a wide range of fields, but especially exposes its advantages in the context of tactical and military use. In areas where conditions are unpredictable and often extreme, clothing made of ripstop fabric offers the necessary protection and durability. Whether for operations in dense forest or in the city, ripstop uniforms provide the robustness and reliability needed to achieve operational goals.

In addition to the military, ripstop also finds favor among emergency services, hunters, and outdoor enthusiasts. Its resistance to mechanical damage and weather conditions makes it an ideal clothing material for people who spend a lot of time in terrain that requires both durability and functionality from their clothing. The fabric is therefore a versatile solution that serves in many demanding situations where quality and durability play a key role.