In the world of tactical gear, every component matters. Buckles, stitching, modular systems – everything must work flawlessly. However, there is a foundation on which the entire design rests and on which reliability in the harshest conditions depends. That foundation is the material. It determines whether your gear will stand the test of time and stand up to the challenges. That’s why the durability of Cordura 500D has become synonymous with quality throughout the industry.

What exactly is Cordura 500D?

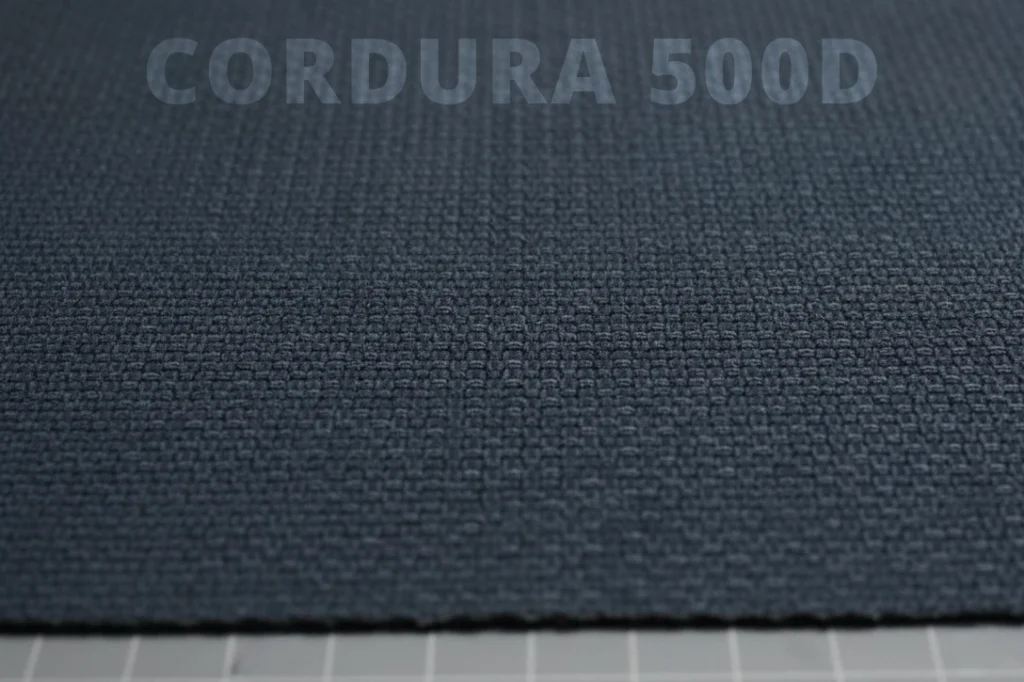

Let’s start with the basics. Cordura is no ordinary nylon. It is a high-tech material, created for extreme resistance. The 500D (Denier – unit of fiber density) version is a specific variant that has gained great popularity in the production of professional armor. Why? Because it offers the perfect balance between two key characteristics: durability and weight.

Cordura fibers are air-textured, which means that during the manufacturing process they are “nudged” and then woven into a dense, extremely strong fabric. This structure makes the material much more resistant to damage than standard nylon fabrics of the same thickness. It is this unique technology that is the secret of its legendary durability.

Resistance to abrasion and tearing in practice

In the field, your gear is constantly exposed to sharp edges, rough surfaces and dynamic loads. It is in these conditions that the true strength of Cordura is revealed. The dense weave of fibers makes the material extremely difficult to abrade. Even if point damage occurs, the special structure of the fabric prevents further tearing of the material.

This is a key feature that directly affects your safety and the life of your gear. A vest or cargo pouch made of 500D Cordura will not let you down at a crucial moment. You can crawl, squeeze through tight spaces and lean against walls, confident that your equipment will remain intact.

Weight versus endurance – the golden mean

There are materials of different densities on the market, such as 1000D Cordura. Although it is even more durable, its weight is significantly higher. In practice, this means an additional load that you have to carry on you at all times. Cordura 500D is considered the “golden mean” – it offers above-average strength, which is completely sufficient for most professional applications, while keeping the weight low.

This results in a lighter weight of the equipment, which translates into greater comfort, better mobility and less fatigue during prolonged operations. This is an ideal compromise that allows you to enjoy reliability without sacrificing ergonomics and freedom of movement.

Weather protection

A good tactical material must cope not only with mechanical damage, but also with the weather. Cordura 500D is inherently waterproof, and is often additionally covered with a special coating (such as PU – polyurethane), which further increases its resistance to moisture. The material dries quickly and does not absorb water, so your gear does not become heavier in the rain.

What’s more, Cordura’s durability also includes resistance to mold, rot and UV radiation. This means that the gear can be used in humid climates without fear of damage, and the color does not fade quickly when exposed to the sun. These are qualities that guarantee your gear will serve you for years, regardless of the conditions.

An investment that pays off

Choosing a piece of equipment made of 500D Cordura is an investment in reliability, safety and peace of mind. It’s reassurance that the gear you rely on has been created from a material that will stand up to any challenge.